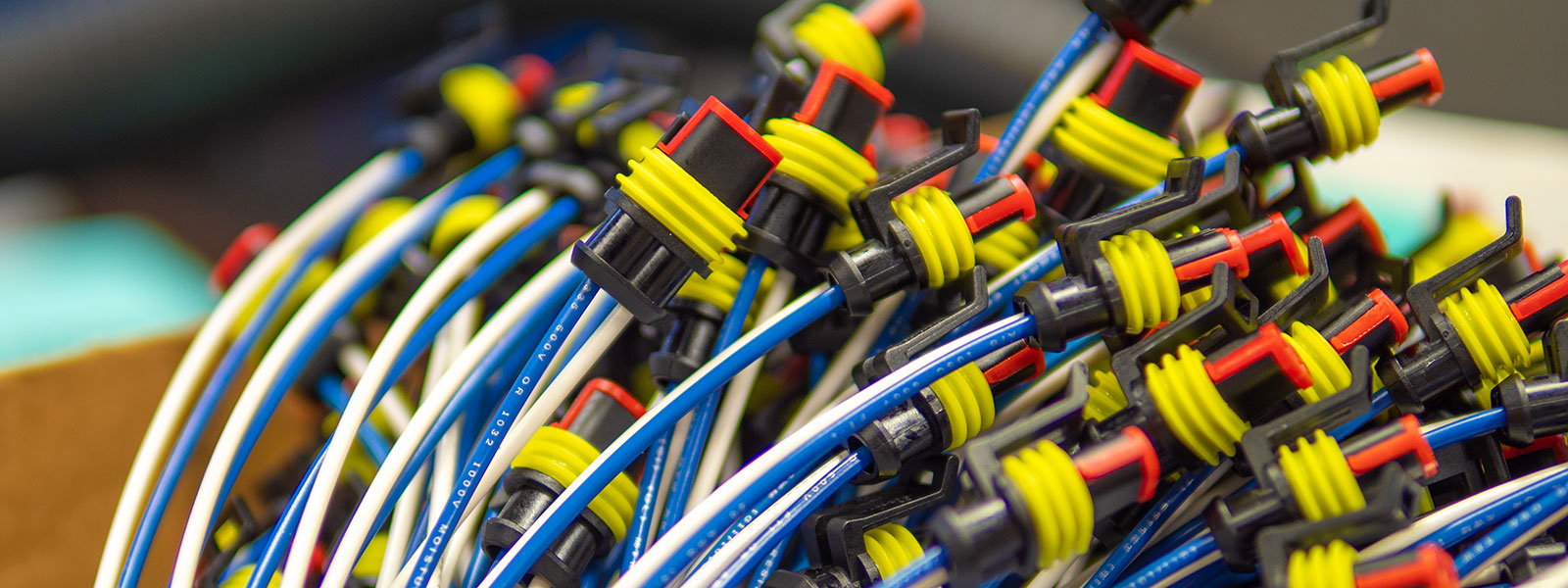

Technical Cable of Washington state, in the Puget Sound area is a cable harness manufacturer equipped to build everything from simple harness systems to extremely custom and complex ones with thousands of connection spots, no matter what your project requires. To explain what all our manufacturer wire harness assemblies include, we can start with the wire. All wires are built using materials that conduct electricity, typically metals like aluminum or copper. If you take multiple wires and tie or attach them together, you now have a cable. Wires often require additional protection and arrangement especially in environments where there is lots of movement or action, which is where our cable harness expertise and manufacturing services come in.

Nearshore Cable and Wire Harness Assembly Manufacturing

The most simple and straightforward type of wire harness has an outside covering that protects the wires inside. The protective covering, often called a “sheath” is often made of thermoplastic material to prevent overheating issues and protect the wires from outside damage. If you were to open up a wire harness, you would usually find multiple wires with their own sub coverings. The package in total makes up a single cable harness. This kind of harness setup is excellent for all sorts of situations where extra protection is required, and may be sufficient for keeping the wires working properly in your average factory, stadium or vehicle process. We can help manufacture your bulk harness production run of wires according to your exact specifications, and needs for safety and reliability. We’re more than happy to build your existing cable harness drawing as-is if you just need to outsource it for increased production, and we’d love to work with you to help you get there. However we also provide custom wire harnesses and can help improve your wires, wire harness or cabling assembly, to meet new requirements or solve process problems the previous iteration had.

Wires and Wire Harness Company

Choosing a manufacturer that is an expert in building the wiring harness you need, or multiple custom wires and harnesses, is an excellent way to save costs and keep your electrical systems safe and organized. Bundling wires and cable systems together makes it easy to set up for building projects so you have fewer pieces to worry about. For indoor environments or temperate outdoor climates, a harness is often sufficient and very cost effective. However a simple electrical harness may not always be sufficient for protection in harsher environments, depending on your situation we may recommend heavy duty options like assemblies. For instance, wires that will be subject to bad weather conditions for at least part or all of the year will need to have a heavier duty sheath incorporating metal or other protective materials to ensure that they will not be worn down by the elements. Another example is for aerospace flight (a growing industry in the Seattle area where Technical Cable Applications is based) where electrical wires will be affected by massive G-forces and pressure changes as they are launched into the atmosphere and return, where we would make sure the materials will be able to withstand that kind of change every time for years to come.

Cost Effective Wire Harness and Assembly Prototyping

A cable harnesses manufacturer like Technical Cable must be equipped with highly skilled workers, to ensure quality and keep costs down by avoiding wasting time with having to remake failed cables. Custom projects that are safe to use more cost effective wiring harnesses are often under tough deadlines and tougher cost constraints, and having a fast, efficient team that can deliver just what you need is one of Technical Cable Applications’ manufacturing specialties. Our assembly manufacturing team takes it the rest of the way with the construction and testing process to ensure that it will deliver based on your wiring needs. Because we can handle all the steps of the production process from prototyping, to testing, and finally to full production, there’s no need to stress about trying to manage working with multiple companies for your cable needs and make sure deadlines are met by all of them. We’ll take care of the entire process and make your custom wire harnesses with excellence and efficiency.

Electrical Cables and Wire Harness Experts For Your Assembly Needs

In conclusion, wire harnesses may be the best option for your project’s needs, but if you need something more heavy duty like a cable assembly we are more than happy to assist with our resources. We are proud to be one of the top electrical wire harness manufacturers in the nation and stand by our quality and delivery speed. Our custom wire manufacturing solutions are of reasonable cost with incredible quality, and we can meet any wires, harnesses or assemblies need you may have. Our assembly engineers are some of the most qualified in the nation and can meet your needs no matter how strict they are in terms of safety, reliability and power. We use the best machining equipment available to ensure that engineering expertise never goes to waste because of poor tools or a faulty automation process. We use only the best parts and equipment to ensure that we can make the best cables possible for your needs, because we know very few industries can afford to have unreliable or low power cables holding them back.

Providing Wire Harnesses and Cable Harnesses Around the World

We have been operating in our Auburn, WA facility since 2002 here in the Pacific Northwest, and have only increased our ability to do more complex production runs, and kept up with the newest technology and electrical cable requirements as all industries and electronics move forward in power requirements year after year. We also now offer nearshore harness assembly manufacturing services thanks to key partnerships with two facilities in Guadalajara, who help us with prototyping, machining and resources and make our services even more cost effective and flexible.

Assembly and Wire Harnesses Experts to Enhance Your Products

Even more recently, after acquiring a Schleuniger 36SP Crimp Center for more excellent automated crimping of our wires and cables, and passing our ISO 9001:2015 certification in 2021, we believe it should be clear to all industrial companies that Technical Cable Applications is more than capable of handling your cable production and machining needs, no matter how strict your process requirements are. Call today so Technical Cable can get started with your project or send us your cable drawing via email.