The Evolution of Cable Assembly Manufacturing

Complexity in cable assembly manufacturing grows incessantly, compelling producers to grapple with intricate designs, precise specifications, and relentless pressure to optimize productivity, while maintaining the quality at the highest possible standard.

Innovation is the linchpin.

Adopting advanced manufacturing technologies and methodologies, including work instruction software, streamlines processes and enhances efficiency, meeting the demands of an ever-evolving industry.

From Handcrafting to Automation

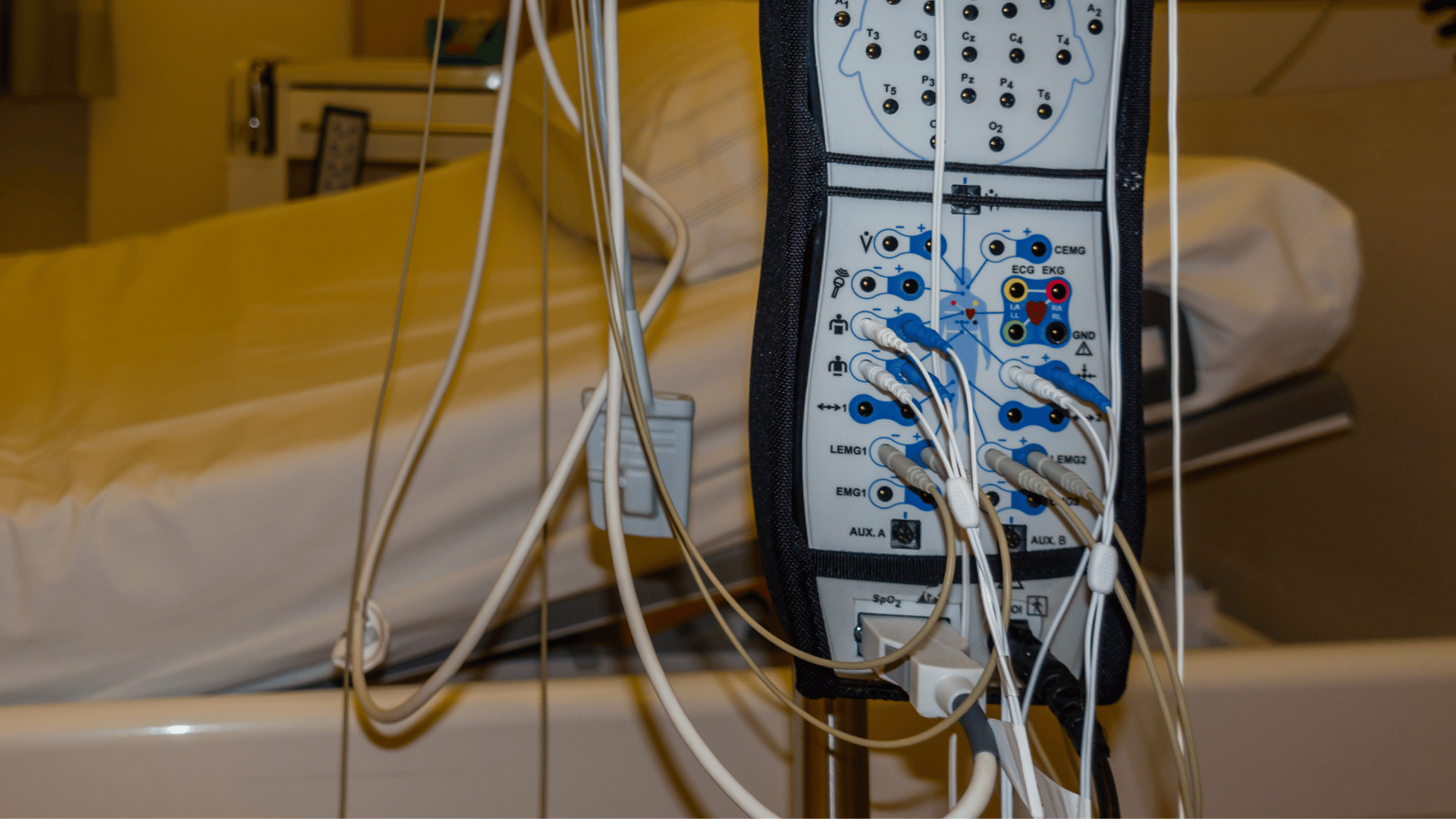

Though cable assembly manufacturing can be an extremely labor-intensive process, cable assemblers are integrating sophisticated automation technologies that bolster consistency, minimize human error, and accommodate the complexities of modern cable assembly production. This evolution supports the aspirations of assemblers and fabricators for heightened productivity, paving the way for unprecedented levels of innovation and customer satisfaction.

Early Manual Techniques

In the initial stages of cable assembly manufacturing, each connection was carefully made by hand. This process was not only time-consuming but also required a high degree of skill and precision, restricting production capacity.

Operators used an array of hand tools, like wire strippers and soldering irons, to assemble cables. Each wire had to be cut, stripped, and soldered or crimped individually, leading to lengthy production cycles.

Early cable manufacture was a meticulous artisanal craft that relied on the steady hands and keen eyes of experienced workers.

Despite advances, these manual techniques established foundational skills and standards that persist in the industry. They underscored the necessity for precision and the value of craftsmanship in creating reliable connections. This groundwork shaped the evolution toward mechanization and automation.

Introduction of Semi-Automated Processes

The advent of semi-automated technologies marked a significant milestone in cable assembly manufacturing, fostering efficiency and consistency.

- Implementation of Cutting Machines streamlined the wire cutting process, reducing the variability inherent in manual cutting.

- Crimping Machines advanced from manual to pneumatic and eventually semi-automatic operation, enhancing connection uniformity.

- Pre-Programmed Stripping Machines offered precise insulation removal, mitigating the risk of wire damage.

- Automatic Soldering Stations provided consistent solder joints while minimizing the potential for human error.

- Work Instruction Software began guiding operators through the production process, ensuring adherence to specifications and minimizing deviations.

With these machines, operators could oversee multiple stages simultaneously, substantially increasing throughput without sacrificing quality.

Investments in semi-automated systems allowed for scalable production capacities, aligning with the burgeoning demand for cable assemblies across various industries.

The Digitalization Impact

The advent of digital technology has marked a significant transformation in cable assembly manufacturing, introducing a new epoch characterized by unparalleled precision and efficiency. Within this digital realm, work instruction software has emerged as a cornerstone, effectively revolutionizing the transmission of intricate assembly knowledge. By digitizing and centralizing instructions, this software mitigates the risk of human error, propelling the industry towards a future where consistency and quality are augmented by an unwavering adherence to detailed digital directives. Consequently, assemblers and fabricators are empowered to exceed customer expectations with every meticulously crafted product.

Future Trends

Advanced materials, including high-performance polymers, will revolutionize the durability and functionality of cable assemblies, shaping customer expectations.

Connected and automated manufacturing processes, leveraging technologies like Artificial Intelligence (AI) and the Internet of Things (IoT), will drive efficiencies and elevate the precision and scalability of cable assembly production, meeting the upsurge in demand for increasingly complex systems.

Digital twin methodologies and predictive maintenance will emerge as standard practices, enhancing product lifecycle management and operational reliability.

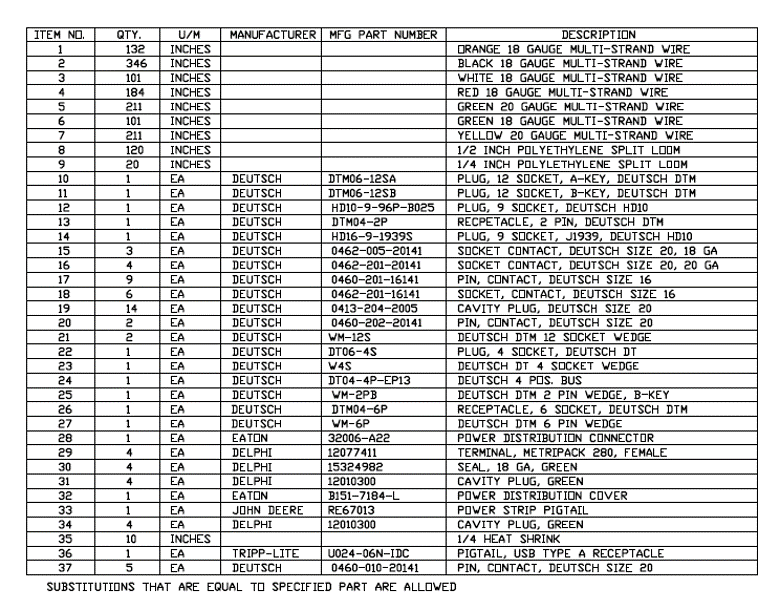

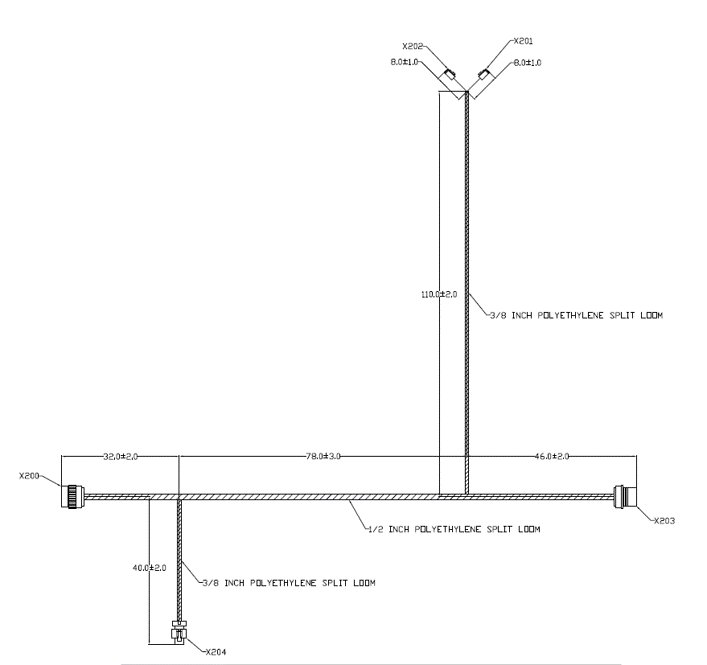

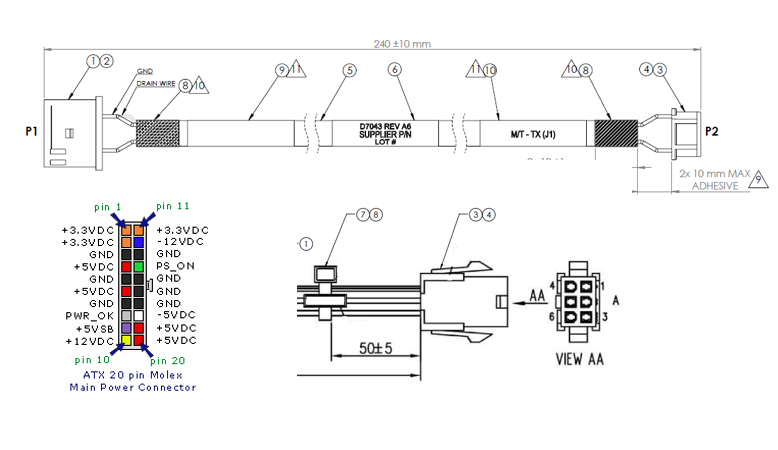

This makes it much easier to identify which parts should be used together and where they should be used.

This makes it much easier to identify which parts should be used together and where they should be used.