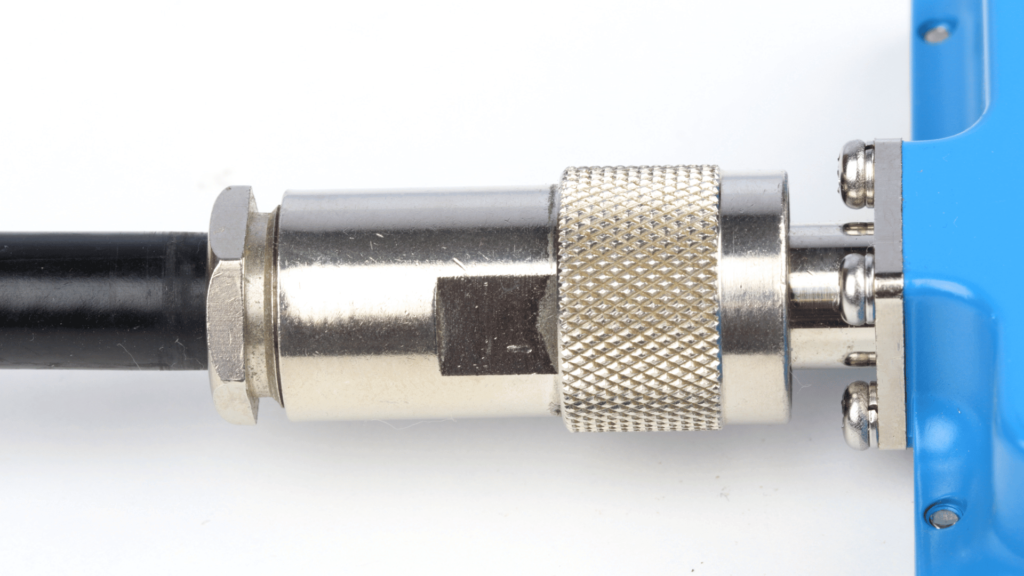

One of the most common custom cable assembly types that we do production orders of is the RF coaxial connector cable, which when combined with other coax cables within a shield makes an RF cable assembly. The RF connector style of coaxial cables is most often used for carrying audio and visual signals with low loss of data, and while it may not offer the same complexity of data as more advanced cable types for video or audio like DisplayPort, SATA, or HDMI, this variant of the traditional coaxial cable is still a cost-efficient and effective way to transmit these types of data, which is important in thousands of different situations across hundreds of industries to this day. Even though coaxial cable connectors and adapters have been in use for an extremely long period compared to more modern connector styles and wire configurations, coaxial cable assemblies and coaxial connectors are still used widely and flexibly for short and long-distance signal transmission needs. RF or SSMA RF cable variations also offer exactly what is needed for many industry scenarios where budgets are tight, but the reliability of video, audio, or data output from cable sources cannot suffer. We also provide cables with connectors SSMA and SMA capabilities, triaxial and biaxial RF connectors, and any other variant of coaxial connectors or adapters you may require.

Whether you need a very basic, off-the-shelf coaxial cable order that will be more reliable than your past options, or if you require an extremely complex, custom RF coaxial cable assembly with an unusual configuration and many other kinds of coaxial connectors and adapters included, Technical Cable Applications has the expertise, experience, and equipment to prototype, test, produce, inspect, and ship out your bulk coaxial cable order efficiently and with unbeatable quality assurance for the cables, connectors, and any required components, accessories, and switches. We’re ITAR-certified for custom cable assembly in the United States and Canada and have produced custom RF coaxial cables with all necessary connectors, antennas, adapters, switches, and cable accessories for thousands of clients since 2002. Contact us today with your cable drawing attached by emailing [email protected], or fill out our online contact form and upload the cable drawing, any required NDAs, and coaxial crimp requirements so we can review your cable assembly order and get started. Please provide as many specifics as possible, such as required ohm impedance, amplifiers, antennas, switches, adapters, power options, and intended usage of the cable and its coaxial connector type.

Whether you need a very basic, off-the-shelf coaxial cable order that will be more reliable than your past options, or if you require an extremely complex, custom RF coaxial cable assembly with an unusual configuration and many other kinds of coaxial connectors and adapters included, Technical Cable Applications has the expertise, experience, and equipment to prototype, test, produce, inspect, and ship out your bulk coaxial cable order efficiently and with unbeatable quality assurance for the cables, connectors, and any required components, accessories, and switches. We’re ITAR-certified for custom cable assembly in the United States and Canada and have produced custom RF coaxial cables with all necessary connectors, antennas, adapters, switches, and cable accessories for thousands of clients since 2002. Contact us today with your cable drawing attached by emailing [email protected], or fill out our online contact form and upload the cable drawing, any required NDAs, and coaxial crimp requirements so we can review your cable assembly order and get started. Please provide as many specifics as possible, such as required ohm impedance, amplifiers, antennas, switches, adapters, power options, and intended usage of the cable and its coaxial connector type.

Custom RF Cable Assemblies

Our cable manufacturing facility in the Puget Sound area of Washington state is one of the most advanced in the nation, not just the Western United States. While we are excellently situated to ship cables to our customers on the Interstate 5 corridor and in the Arizona area as well with our sales department extension in Phoenix, we also serve customers all over the States every year with our custom and off-the-shelf cable solutions. We even ship custom RF and coaxial cable orders internationally, so please contact us even if you’re overseas. We pride ourselves on being the best choice regardless of whether you need an off-the-shelf coaxial cable manufactured more efficiently to increase your production quality and speed, or are coming to us in need of a custom cable solution, as we manufacture all coaxial cable assemblies and cables to exact standards and are UL certified for cable assembly in the United States and Canada. We also employ extremely creative cable engineers and technicians who relish the challenges that arise with custom coaxial cable manufacturing. We also keep a strong inventory of coaxial connectors, adapters, cable material, and parts as much as possible throughout the year, so we have the best chance of getting right to work with prototyping and testing a custom flexible coax cable solution for your required cable type as soon as possible. Choosing TCA for your cable needs gives you the power to complete your broadcast, product, or facility improvements more efficiently and with higher quality control.

We also keep a strong inventory of coaxial connectors, cable materials, adapters, and parts as much as possible throughout the year, so we have the best chance of getting right to work with prototyping and testing a custom cable solution with your required coaxial connectors, adapters, and antenna types as soon as possible. Our cable inventory management system is extremely advanced to meet and exceed UL requirements so we can always account for every single component, material, and connector we use and find exactly where an issue occurred if we uncover a cable quality issue during inspection. This also means we can find out exactly whether we have the parts needed for a new cable order in-house, or if an order will be needed for a more unusual coaxial connector type that we don’t have sufficient stock in due to its rarity. We avoid this wherever possible although for very old or rare coaxial and RF connector types, it is not always possible. However, we have done an excellent job in maintaining a well-stocked inventory on hand of adapters, materials, amplifiers, and parts even during the peak of the COVID-19 pandemic and continue to do so now. Thirdly, we use advanced and powerful equipment to ensure that repetitive or strenuous tasks are done correctly every time and more quickly too. For instance, the Schleuniger 36SP Crimp Center we utilize for coaxial crimp and tinning allows us to accomplish the same work we did before much faster, and just as precisely. These types of investments in the best and most cutting-edge cable production technology available allow us to push the boundaries of what’s possible with coaxial cable assemblies, coaxial connectors, and adapters and provide solutions to your cable problems with ohm impedance, signal loss, or durability that other custom coax cable manufacturing companies would be baffled by.

Custom Coax Assemblies

Our manufacturing staff is extremely experienced and well-trained, building hundreds of coaxial cables rapidly with high efficiency, in-depth knowledge of their craft, and an eye for quality above all else. We intentionally hire the best employees we can, and retain our staff as best we can with competitive pay and benefits as while we may use the most advanced equipment wherever possible to minimize mistakes and maximize efficiency, our excellent cable assemblies manufacturing staff and their passion for quality is what has always set us apart. We also work with two excellent facilities in Guadalajara for nearshore manufacturing which has helped lower turnaround times and MOQs for more mobile and flexible prototyping, while also improving quality control as we have direct access in these partnerships to oversee part and assembly builds. We are also ISO 9001:2015 certified for cable assembly and hold to the IPC/WHMA-A-620 – Revision D procedures standard for all of our quality inspection methods. Finally, we utilize extremely detailed, automated work instruction systems developed with our partners at Scout Systems which have helped and continue to help us greatly improve all of our assembly and manufacturing processes both in efficiency and end product quality. Choose Technical Cable Applications and send us your coax cable drawing today so we can get started! Don’t forget to include any required NDAs and any other specifics you can about adapters, switches, ohm impedance, material requirements, etc.

What certifications does Technical Cable Applications have?

We are proud to hold the following certifications that attest to our commitment to quality and compliance:

– ISO 9001:2015 Certification

– ZPFW2.E363245 – Wiring Harnesses Certified for US – Component

– ZPFW8.E363245 – Wiring Harnesses Certified for Canada – Component

– ITAR Certification

– UL

How can I get a quote for my custom RF cable bulk order?

You can fill out our contact form at https://www.technicalcable.com/contact/ or email us at [email protected]. Please attach your cable drawing, specifications, any required NDAS, and information about required adapters, materials, etc. Everything you can provide us with makes it easier for us to give you a quicker and more accurate quote.