Custom Cable Manufacturers - Custom Cable Assemblies

The company of tomorrow connecting you today.

Contact Us

Hours & Address

2840 W Valley Hwy N #102,

Auburn, WA 98001

Mon-Fri: 7:00 to 4:00 PM

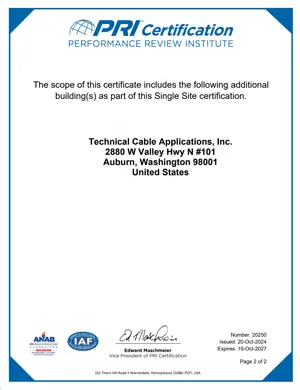

Certifications & Standards

About Technical Cable Applications - Your Quality Cable Experts

Technical Cable Applications is a contract cable manufacturer specializing in the field of custom cable assemblies and custom wiring harnesses. With a huge selection of automated and manual tools, equipment and parts to prepare outsourcing cable assembly products, Technical Cable can build your custom cable assemblies to specification and inspect the finished assemblies for perfection. Our engineers and technicians are highly qualified and trained, and we have experts for each part of the prototyping, manufacturing, and testing processes that any full cable manufacturing project requires.

Your Bulk Cable Assembly Manufacturer for Custom and OEM Solutions

We hold ourselves to extremely high cable standards and are UL certified for the United States and Canada for cable assembly, along with our ITAR certification for United States defense manufacturing. We are also ISO 9001:2015 certified as a contract cable manufacturer, which is an internationally recognized standard. Finally, we follow the quality control procedures as dictated by IPC/WHMA-A-620 Standard Revision E to ensure that each of our cable assemblies and wire harnesses are manufactured perfectly every time.

At Technical Cable Applications, the first and most important step of the cable manufacturing process is confirming your specifications. Manufacturing custom assemblies and harness assemblies requires custom solutions. Each assembly production is different, and each custom cable project brings forth new and exciting engineering. We constantly innovate and invest in new solutions and tools to speed up and improve our cable manufacturing processes. We also hire only the best engineers and technicians to prototype new builds, so that we can continually push the envelope and grow our manufacturing and custom prototyping capabilities each year. We're happy to provide custom cable products so your updated cables can meet and exceed new regulations for your industry for power, safety, and reliability, or just upgrade your product line if you require an edge over your competitors.

Ready For Any Custom Cable Order

Technical Cable Application's prototyping team works with the highly qualified custom cable engineers and cable assembly team on our staff. Together, they work to make sure that the services and parts needed are assembled and delivered perfectly. Technical Cable Applications performs manufacturing solutions quickly, without losing sight of the customer’s need for custom services and high-quality results. We keep the parts and tools on hand for most typical cable styles and connectors so that we can get to work right away on bulk orders of pre-existing or "off the shelf" assemblies, while also keeping our innovative engineers on site to assist with every new project we take on, and maintaining strong relationships with material providers so that we can order anything additional needed for a new project quickly. We can manufacture hybrid cables utilizing an extremely wide variety of connectors, components and conductor parts from all kinds of brands, such as Molex, TE, Hirose, JST or Mouser. Just provide your cable drawing so we can see what you're working with and request a quote.

Cable Manufacturers - Choose TCA For Wire Harness and Cable

With your specifications, TCA orders any additional parts needed to begin proper cable assembly production. Automation has been developed for aspects of contract cable and harness assembly like automated wire cutting, stripping, crimping, 3D printing, and injection molding. We use automated work instruction systems developed in partnership with Scout Systems, which enable us to not only make our cable manufacturing as efficient as possible, but also improve our processes by letting us identify wasted effort and time more easily. Much of the work is custom and hand made as well, by IPC certified and trained cable technicians when necessary. Our team of technicians are experienced and qualified, and always ensure that every wire and cable they touch is assembled properly and carefully. A tour of our manufacturing facility will show that we are the cable manufacturer to trust as we are extremely rigid about quality control, inventory, and best practices not only to continue meeting our UL certifications which are randomly audited, but also because that's how we've operated our business since being founded in 2002.

The Cable Manufacturer Process

At TCA, wire cutting is often the beginning of many projects if the cable drawing is already in place. This phase is mostly automated with our robotic despoiling and wire cutting machines to produce the correct cable lengths. Followed by stripping and adding custom connectors, the cable is stripped back to reveal its copper or other metal core so the next steps of cable assembly can be completed. This automation and the special machines that utilize it allow us to start with an extremely solid beginning for every cable and wire before further steps are completed.

With the cores exposed, custom connectors or conductors can be added. Doing this includes crimping and soldering the wire into the proper connections. Many manufacturing steps in this part are automated as well, and those that cannot be automated are done by hand by skilled custom operators. We are continually improving our crimping and soldering processes by acquiring new tools and machines, including the extremely powerful Schleuniger 36SP Crimp Center. Using the best and most powerful machines for precise work means that quality assurance is involved in every step of our cable manufacturing processes.

After the crimping and soldering processes have been completed, the terminated wires are gathered up and crafted into the contract harnesses themselves. This step requires most of the manual wire work from our technicians. Each wire is fed through or bundled together, taped off and measured to make sure the final dimensions match the manufacturer specifications. Technical Cable Applications adds coverings, braiding, heat shrinkable tubing, transition boots, and tubing products as required.

Cable Manufacturing Company Equipped For Your Products and Their Cable Requirements

When the cable manufacturing or wire harness manufacturing is finished, a thorough inspection is completed of all assemblies, to inspect compared to the drawing for dimensions, continuity, and note compliance. Each step in the product inspection procedure is monitored and tracked. In the event of any failure to pass our strict tests for quality, we will immediately address and locate the issue, make it right, and ship quickly to ensure minimal delays. Any manufacturing failures are always fixed, and the parts are retested and sent to shipping when the manufacturing is approved. We partner with reliable and efficient shipping partners so we can manufacture and ship our products almost anywhere around the world.

Producing Custom Cable Solutions For Over 20 Years

Overview of our Leadership Team:

- Dale Twiggs, President and Founder

- Dustin Twiggs, Vice President

- Sean Stenhouse, Sales Supervisor

- Ian Rutherford, Account Manager

- Blake Twiggs, Account Manager

Our leadership is committed to excellent quality cable manufacturing above all else, and we are constantly looking for ways to innovate and improve our processes, facility, and partnerships while taking care of our staff and ensuring they are equipped to do great work with every cable and wire harness we produce. We utilize several different methods and standards for quality control with our custom cable production such as IPC/WHMA-A-620 Standard Revision E, and are ISO 9001:2015, ITAR and UL certified for cable assembly. We also take advantage of advanced tools to reduce variance wherever possible, i.e. our automated work instruction systems developed in partnership with Scout Systems that ensure every step of manufacturing is done properly, every part and connector can be traced back to its origin, and every procedure can be optimized for maximum efficiency.

Founded in 2002 and operating out of Auburn, WA in Washington state, Technical Cable Applications is a cable manufacturer for tens of thousands of completely custom contract cables, and many high quality wire harness orders per month. We work with clients all over the United States in dozens of industries, including construction, telecommunications, healthcare, industrial manufacturing, and many more. If you have a large project requiring custom cables or a bulk order of high quality harnesses, we have you covered as your one-stop cable manufacturing expert. There's no need to work with multiple manufacturers all over the nation, when Technical Cable Applications can take care of the entire project on your behalf.

We have partnered with two prominent nearshore cable manufacturing facilities in Guadalajara to enhance our clients' experience, with higher quality part manufacturing, shorter lead times, and lower MOQ requirements which all provide superior final products for our customers. Working with these facilities directly in favor of offshore facilities for improved quality control, faster shipping and reduced cost in many cases has proven to be extremely beneficial for us, and choosing Technical Cable Applications is an excellent way to indirectly benefit from nearshore manufacturing for your business.

Whether you need high speed data cables to utilize your business' fiber Internet access, complex harnesses for huge construction projects that must be extremely durable to survive outside, or a custom coaxial cable solution to power your telecommunications company's expansion efforts, Technical Cable Applications is the trusted American cable manufacturer to turn to. Our facility is in the Pacific Northwest which is an excellent place to work, and close to hundreds of industry leaders in the Pacific Northwest's Silicon Valley, but we serve the whole country and can ship all over as you require it for your cable needs. We also ship internationally, so please request a quote for your custom cable requirements and don't forget to attach your cable drawing!

Call TCA today for any needs involving custom cables or bulk cable, wire and harness orders!

Technical Cable Applications has been in business since 2002 and is constantly pushing the boundaries on cable assembly.

collaborative thinking to further the overall value proposition.

Technical Cable Applications can build very simple harnesses or extremely complex harnesses with hundreds of harnesses.

Coax cables are typically point to point assemblies designed to carry a radio frequency signal from one point to another.

TCA utilizes MoldMan thermoplastic machines to over mold assemblies for cables by the thousands.

Wire cable assemblies are problem solvers in electrical industries.

Industrial Ethernet cables are the industry standard for rugged data connections.

Contract manufacturers are companies that contract with a firm for parts or products.

Contact us to learn how our experienced team can build your custom cables, harnesses and assemblies, and inspect the finished goods for perfection.

Get Started Now!A sales representative will make sure all of your custom cable manufacturing questions are answered.