Technical Cable Applications Inc. is a contract manufacturer of custom cable assemblies. Based in Washington state and operating since 2002, we are your cable and wire manufacturers and work with many industrial partners in the Pacific Northwest and United States as a whole. We have clients in all kinds of industries, including automotive and industrial manufacturers of all sorts of products and construction projects. Our staff is highly trained and prepared to manufacture nearly any cable or wire harness, for all sorts of applications and purposes.

Technical Cable Applications can provide all sorts of cables and wires for your bulk needs. Here are just some of the many services we offer:

- Battery Cable Manufacturers

- Cable Fabrication

- Cable Molding

- Cabling Manufacturers

- Coaxial Cables

- Construction Cables

- Contract Cable Manufacturing

- Contract Manufacturers of M12 Cable

- Custom Cable Makers

- Custom Cable Manufacturers

- Custom Fiber Optic Cables

- Custom Medical Cable

- Custom Molded Cable

- Custom Ribbon Cables

- Custom RF Cable

- Custom Wire

- ECG Cables

- EV Cable Manufacturer

- Fiber Optic Cable Manufacturers

- High Voltage Cable Manufacturer

- Industrial USB Cable

- Industrial Cable Manufacturers

- M12 4 Pin Connector

- M12 Cable Company

- M12 Cable Manufacturer

- M12 Connectors

- Prototype Wire

- RF Coaxial Cable

- Telecommunications Cables

- Triax Cables

- US Wire Manufacturers

- USB Cable Manufacturing

- Wiring Manufacturer

- Wiring Supplier

We can also fulfill bulk orders of any size as needed, whether you need M12, Molex, Ethernet, or other cable connector types for your manufacturing or construction needs. Our capabilities in the manufacturing of cable assemblies, wire harnesses, and much more mean that you can always come to us with your cable manufacturing needs. While the COVID-19 pandemic as of 2020 has made it more difficult for most manufacturers to obtain the materials they need, we do our best to keep the most common connectors on hand for testing so we can make sure your custom parts can be prototyped quickly. Meanwhile we are partnered with great suppliers who make great quality connectors and parts so we can get your order completed as efficiently and quickly as possible.

The assembly types indicated below are just a sampling of the connector interfaces and cable types we are tooled for contract manufacturing:

Battery Cables: As a contract manufacturing company, we modify a wide variety of large gauge battery cables. These can require large hydraulic crimps that cannot be operated by hand, or very large-handled crimp tools. Sizes that range from standard electronics wire sizes up to 000 AWG. We recently acquired a Schleuniger 36SP Crimp Center which allows us to perform even more precise and automated crimps to cables as needed, so no matter the specificity of your project we have the tools needed.

Coaxial Cable Assemblies Connector: types include BNC, F, MCX, MMCX, N, SMA, SMB, TNC, and other proprietary types. We can manufacture assemblies from twin-axial and triaxial cables, with solder or crimp style connectors. Our manufacturing results in the best product on the market.

Flat Cables: We manufacture flat cables with IDC crimps with large arbor presses, twisted pair flat cables, and other specialty parts. We can modify and manufacture some kinds of flat flex cable.

Jumpers: We make thousands of single wires with connectors on one or both ends such as flags, QC terminals, or ring terminals. We use a high degree of automation for these parts for high quality, cost savings, and repeatability. Through the process of manufacturing using the best tools and equipment available, we yield products that will serve your company best.

Cable Manufacturing

Wire Assemblies: We automate wire cutting and stripping of a wide swath of wire sizes and types. Tinning, labeling, twisting, and other wire assembly services are available. Careful wire assembly manufacturing allows our products to speak for themselves.

Molded Assemblies:We overmold parts locally in our Auburn, WA facility using low pressure injection molding of thermoplastics. Overmolded parts and services include backshells, grommets, and PCB encapsulation. You’ll see in our company contract that our process for production results in high quality products. The many companies we work with are pleased with our contract manufacturing and company standards.

Round Cable Assemblies: We assemble and automate the processing of round jacketed cables for extra environmental protection, sealing, improved airflow, and space to contract savings. The manufacturing involved is always maintained by our satisfaction guaranteed contract.

Test Harnesses: We build custom cables for testing, including probe cables, prototypes, specialty one off cables for destructive testing, and instrumentation cables. Without outsourcing, our localized contract production is why our manufacturing is always high quality.

You never need to worry about whether our bulk production run of your cable drawing will work properly. We test and prototype custom cables to ensure that they are exactly right before going to production. Our engineers are extremely experienced and know just how important it is that your cable run works perfectly, no matter whether you have 100, 500, or 1000 cables produced by us.

Wire and Cable Manufacturer

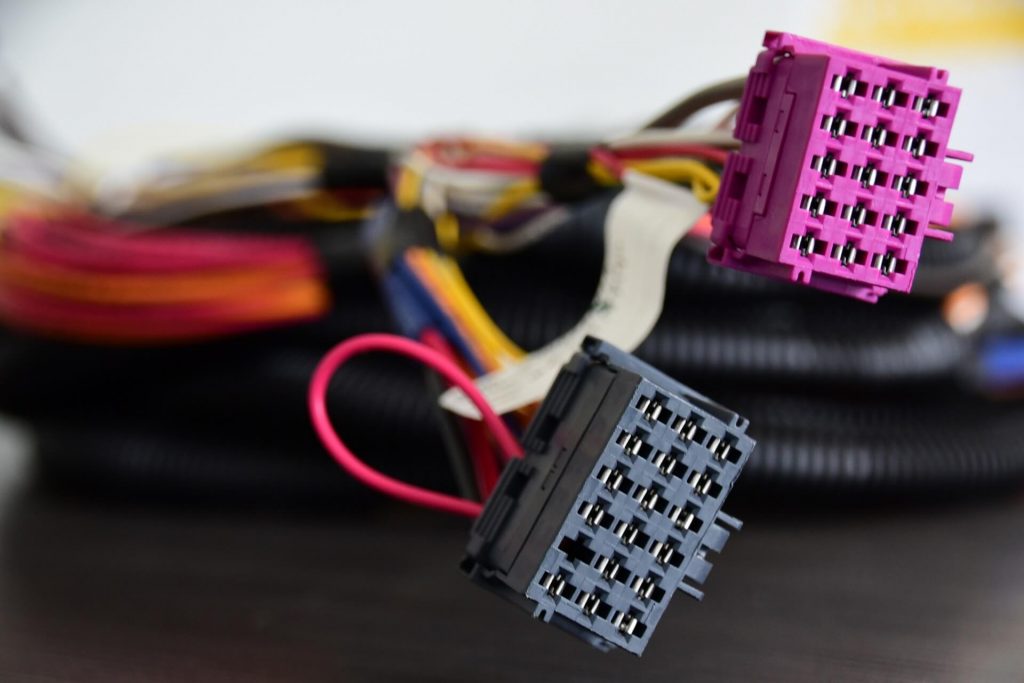

Wire Harnesses: Contract cable manufacturers create large custom wiring harnesses with many connectors for wiring components past firewalls, engine harnesses, and large equipment harnesses. The manufacturing for these products are built with high quality workmanship by our contract manufacturing team. There is no need to worry that your contract cable manufacturer will produce poor quality cables and wires when you can choose Technical Cable Applications. We are ISO 9001:2015 certified so our products and manufacturing practices not only meet the standards for American quality for electrical applications, but also are good enough for ISO’s international standards. We’ll ensure that our cable or wire solution is compliant with your requirements for quality and power as well.

Call Technical Cable Applications today with your manufacturing needs or cable drawing, and we’ll get to work!