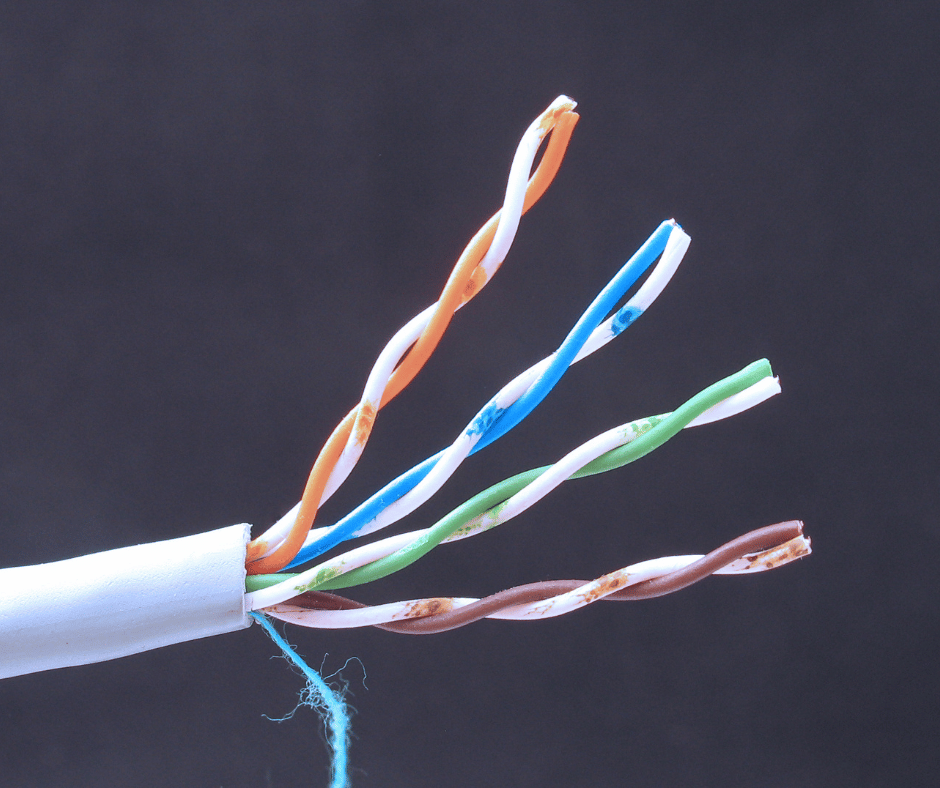

Need a better cable manufacturing solution for your networking, data Ethernet, and telecommunication products or facilities? Technical Cable Applications is here to be your partner and supplier for twisted pair cables, parallel pair plus pair cable of all types, shielded cable, fiber optic cables, and coaxial cables, along with so many more types of cables, connectors, sensors, and switches for any automation, electrical, or battery power needs as well. If you’ve got a drawing with all the details of materials for your custom twisted pair cable assembly, we can almost certainly make it for you at scale! Just submit your drawing via our online form or email us at [email protected], or send NDAs if needed before the drawing can be reviewed.

Your Source for Custom Low Voltage Cable, Shielded Cable, Twisted Pair Cable, and Parallel Pair Cable

Technical Cable Applications has evolved into one of the leading manufacturers and suppliers of networking and telecommunications cables and cable assemblies in the United States, experiencing continuous growth since its founding in 2002. Based in the Seattle area, sometimes called the “Silicon Forest” as it is one of the top tech hubs in the nation rivaling the famous Silicon Valley, TCA’s experience with all kinds of network and data cable assemblies means we are the best partner to choose when you’re looking for high quality, reliable cable manufacturing. We also service clients from dozens of different industries, including telecommunications, automotive, marine, medical, construction, energy, and agriculture. We have decades of experience, highly advanced equipment, and top engineers and technicians working on every cable carefully.

OEM Twisted Pair Cabling or Low MOQ Custom Solutions: TCA is Flexible with Your Needs

Suppose you have an existing cable drawing or OEM cable that needs to be produced with more reliability, shipped with improved turnaround times, or only made with nearshore-built materials. In that case, Technical Cable Applications is an excellent choice for scaling as our headquarters in Washington state, and our partnerships with two fantastic facilities in Guadalajara allow us to manufacture almost anything onshore or nearshore, with far less reliance on overseas materials and parts than many of our competitors.

Meanwhile, if you require a custom prototype or unusual solution that is only a drawing and hasn’t been manufactured in any scale yet, we can handle that too. Our nearshore manufacturing capabilities once again beat the competition, as they also allow us to offer lower MOQs (minimum order quantity) and quicker turnaround times for custom manufacturing as well, just like the previously mentioned OEM cable types.