TCA has been building high quality OEM and custom electrical cable assembly harnesses since our founding in 2002 for business partners in dozens of industries and specializations. Every engineer in our team is extremely knowledgeable and experienced with the production of custom cables and cable assemblies in the following industries and their associated cable types and products, and we are grateful to our business partners who refer new customer contacts to us. There are many more industries besides what’s listed here that we have just as much engineering experience with, so please call us with your cable drawing and requirements to learn more about how we can best support you!

- Automotive

– Battery cable assemblies

– EV charging cables

– Infotainment display cables

– Engine wiring harnesses

– M12 cables for factory automation - Telecommunications

– Coaxial cable assemblies

– Ethernet cable

– USB and Thunderbolt cables

– DisplayPort and HDMI cables

– Ribbon, flat, and flex cable assemblies - Construction

– Shielded cable assemblies

– Overmolded cable assemblies

– Underground power cables

– Heat resistant cables

– Fiber optic cables

Custom Electrical Cable Manufacturer – Nearshore OEM and Custom Assembly Solutions

Technical Cable Applications proudly offers nearshore cable manufacturing, with the ability to prototype, test, and manufacture custom cable assemblies with minimal reliance on overseas production. Of course, our ability to avoid the hassle of overseas tariffs for cables, materials, and parts depends on the industrial connectors and specific materials needed for any given cable assembly; ask us for more specifics about our sourcing if you require a North American custom cable manufacturer. Don’t forget to also include your cable drawing or any NDAs that need to be signed before we can review drawings. Just contact us at [email protected] and we’ll quote you for your cable assemblies order as soon as possible!

Our nearshore capabilities also greatly enhance our ability to provide custom wire harnesses and cable assemblies with shorter lead times and lower MOQs (minimum order quantity.) This means if you are stuck in the prototyping process for your custom cable assembly solutions or wiring harness needs due to cost concerns or delays with another cable assembly manufacturer, which does everything overseas, choosing Technical Cable Applications will help you get through the cable prototyping phase more quickly and with more flexibility and quality to boot. However, if you require a North American manufacturer for your OEM cable assembly or wire harness, our quicker turnaround times will also be an excellent boon. Rather than being less efficient due to keeping as many of our processes nearshore, we have been able to improve our lead times and simplify budgeting for our customers, and are continuing to emphasize nearshore as much as possible for all of our cable assembly solutions.

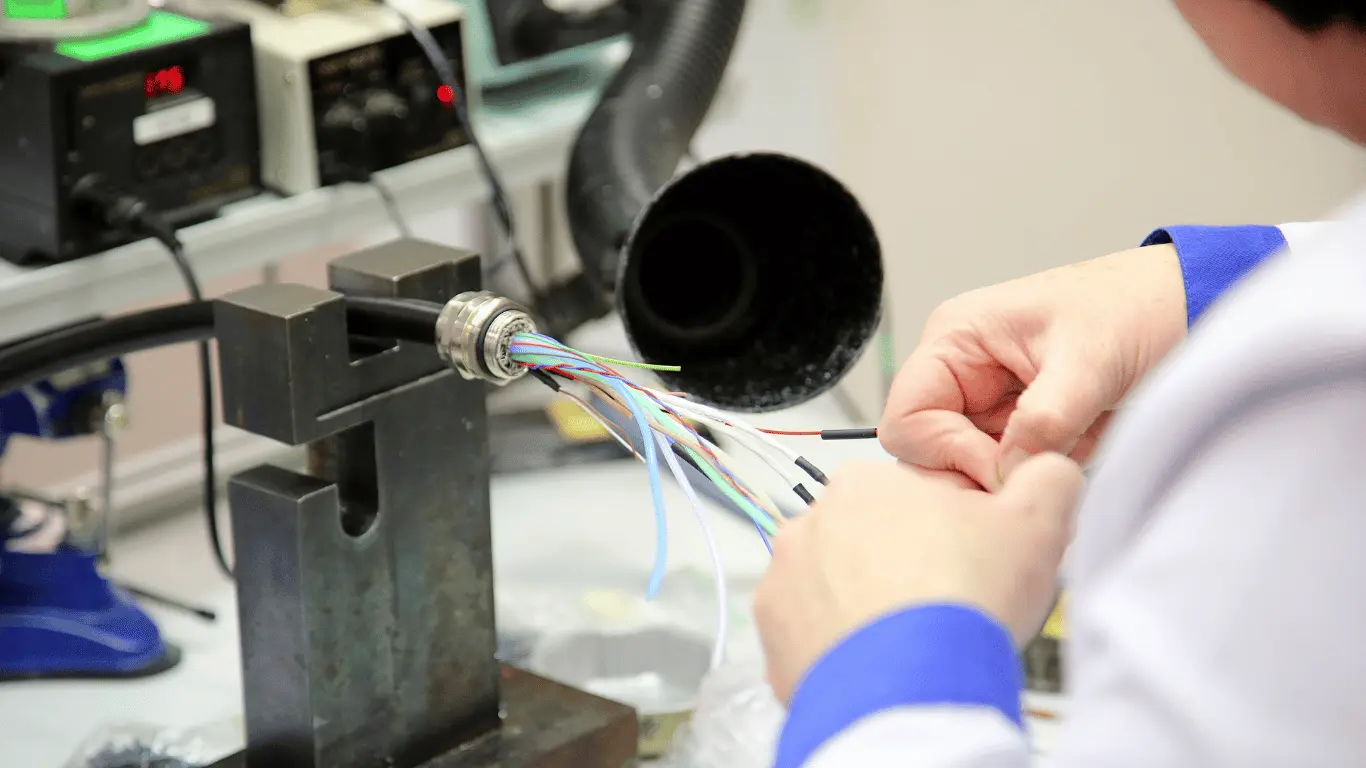

Custom Overmolded and Shielded Cable Assemblies for All Industries

One of the most common needs for many different industries is overmolded shielded cable assemblies to carry power and data through outdoor, extreme temperature, or densely populated areas without loss of power or data, or worse, risk of injury to customers, employees, or civilians. Built with anywhere from two to hundreds of wires internally, our protective cable assembly and cable snake capabilities are unmatched. We can provide custom or OEM overmolded cables that will meet or exceed your industrial safety requirements, with extremely rigid quality control standards that are enhanced by our direct partnerships with nearshore facilities.

We have direct oversight of these manufacturing facilities, and our adherence to the industrial quality control standard of IPC/WHMA-A-620 Standard Revision E means that we know exactly where every part, material, and connector came from and can identify what caused any cable failures identified in quality control. We are also globally ISO 9001:2015 certified for cable assembly, and UL certified for cable assembly in the United States and Canada. We also utilize automated work support instruction software and hardware from our partners at Scout Systems, which allows us to constantly improve our processes and identify points of efficiency loss.

Ready to get started? Send your cable drawing, requirements, quantity needs, and any required NDAs or agreements to [email protected] or give us a call today.