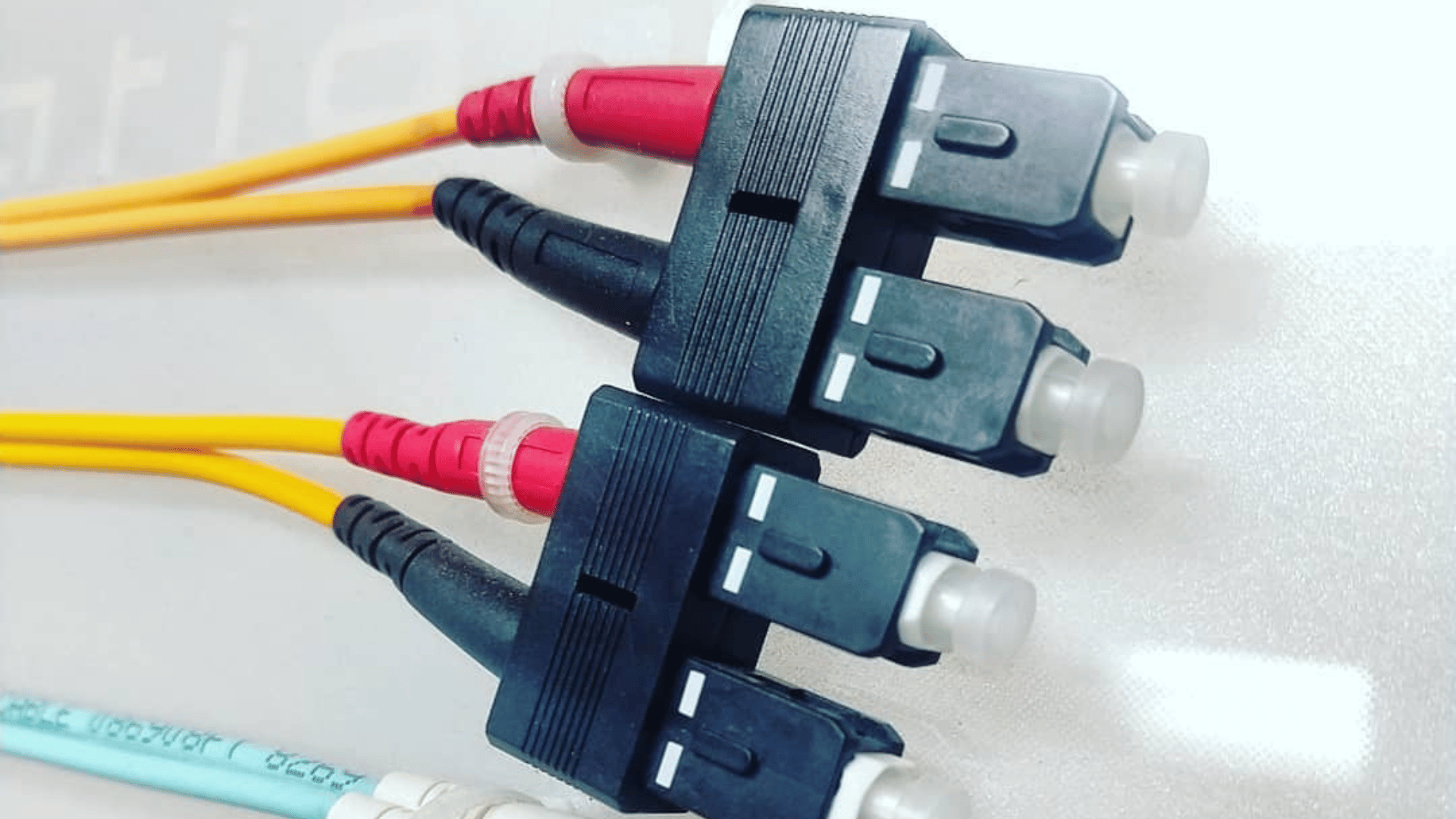

Founded in 2002 by Dale Twiggs, Technical Cable Applications is dedicated to providing the best possible services and cable harnesses and cable assemblies on the market that meet your exact needs. Our team of engineers and technicians is highly qualified and experienced, and has helped manufacture solutions to new problems and keep our customers on the cutting edge of technology services for the past 22 years. Whether you need M12 cable assemblies for automation, coaxial or RF cable assemblies for data transmission, medical cable assemblies for healthcare applications, fiber optic/Ethernet cable assemblies for network management, or battery cable assemblies for military applications, Technical Cable Applications can provide off-the-shelf and custom cable assemblies with extreme quality control, competitive pricing, and excellent customer services. Your success is our success, and we hope to keep you on as a customer for decades to come after your initial order with continued cable manufacturing services and many future products.

Our leadership team is dedicated to manufacturing excellent cable products and providing world-class services and cable assembly solutions. You can learn more about our company history and services on our About page.

– Dale Twiggs, President and Founder

– Dustin Twiggs, Vice President

– Sean Stenhouse, Sales Supervisor

– Ian Rutherford, Account Manager

– Blake Twiggs, Account Manager

Custom Cable Assembly Solutions and Cable Assemblies Manufacturing

Technical Cable Applications is one of the top custom cable solutions manufacturers in the United States and beyond, providing hundreds of thousands of industrial cable assemblies to our customers throughout North America and elsewhere every year. We provide custom cable assemblies and OEM cable assemblies with full in-house cable assembly prototyping, testing, manufacturing, inspection, and shipping services, so you can trust us with the entire process of your cable assembly order, rather than having to coordinate with multiple businesses and deal with the complications that come with a fragmented cable production process. Just send us your custom cable request via our online contact form, or send your cable drawings to us at [email protected] so we can get started on engineering your high quality cable assemblies order!

We provide engineering and production of hundreds of styles of cable assemblies and cable products, with almost any custom cable connector or configuration you can think of. Whether you need ribbon cable assemblies or flex cables for infotainment systems in vehicles, Cat-6 cables for data centers, M12 cables for automated warehouses, integrated microwave assemblies, or any other kind of custom cable assembly, Technical Cable Applications will be your quality cable manufacturer. Our assembly solutions will be your best asset!

We are proud to partner with two excellent cable facilities in Guadalajara that offer nearshore cable manufacturing solutions, and work with us very closely in all the steps of cable production and manufacturing. This allows us to save cost on cable products and improve quality control compared to overseas cable manufacturing services, which most of our competitors have to utilize exclusively. We can also avoid the complications associated with overseas shipping, and have faster lead times and lower MOQs for customized cable products and orders as well. If you’re exploring how to take advantage of nearshore manufacturing cable for your business and the industries it serves, partnering with Technical Cable Applications is a great way to start!

Custom Cable and Off the Shelf Ribbon Cable Assemblies

Technical Cable Applications is internationally ISO 9001:2015 certified for the manufacturing of cable assemblies, along with being UL certified for cable assemblies in the United States and Canada. We are also an official ITAR-certified cable manufacturer and hold to IPC/WHMA-A-620 Standard Revision E for our quality control procedures. Finally, we utilize automated work instruction system services made in collaboration with our partners at Scout Systems, that allow us to identify problems and modify or learn how to improve cable production processes that are inefficient or wasteful. This allows us to constantly improve and streamline our manufacturing of cable assemblies and pass those improvements on to our clients.

We would love to go over your cable requirements with you and provide an expected pricing, timeline, and all the other details you need to learn before making a decision for who will be manufacturing your cable assemblies. You can start now and request a cable services quote by using our online contact form, or give us a call! Please provide any cable drawings and specifications for cable assemblies you have and/or required NDAs as applicable.