In need of a highly reputable cable assembly supplier, with nearshore manufacturing capabilities and meticulous quality control? Technical Cable Applications is the partner for you! With our main headquarters located in the Silicon Forest of the Pacific Northwest, and qualified partner facilities in Guadalajara, we are able to offer assembly manufacturing of custom cables or OEM cable assemblies with quick turnaround times. We also are able to offer low MOQs for custom wire needs, while having the capacity for massive OEM wiring harness orders with thousands of wire harness assembly units as well.

This makes choosing Technical Cable Applications for your cable assemblies and wire harness needs could be a massive lift for your business, product, or facility’s efficiency, power, and safety. Curious to learn more or have a drawing ready to go for your custom cable assemblies or OEM harness assemblies? Send it or any required NDAs to us at [email protected] to get your custom quote, and make sure to include any questions or specifications about materials, connectors, and parts!

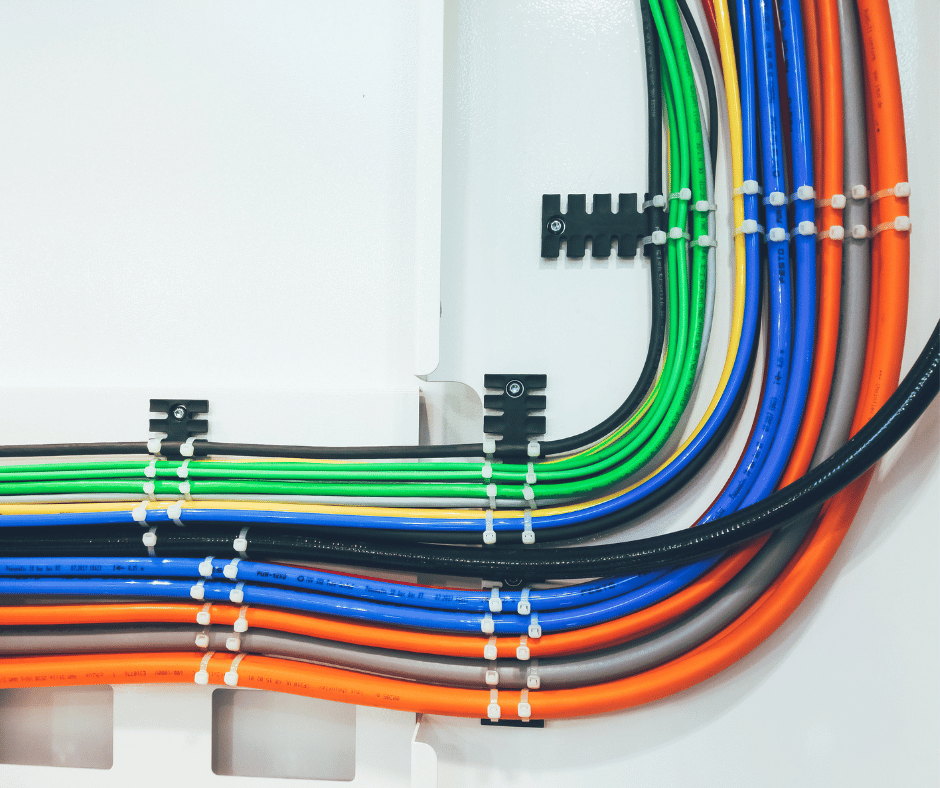

Your Source for Custom and OEM Harness Assemblies and Wire Harness Manufacturing

Founded in 2002, TCA has been providing production solutions for OEM cables and custom assembly cable to thousands of clients for over two decades. However, we have grown significantly during that time. Expanding our main facility multiple times, acquiring highly advanced cable custom equipment, and partnering with two Guadalajara facilities has allowed us to offer an extremely wide range of custom cable and OEM cable solutions. Our staff are some of the most qualified engineers and wire processing technicians in the business, but we take zero chances and hold to some of the most exacting quality control standards in the cable assemblies industry.

Certified North American Cable Assembly Manufacturing

We are UL certified for manufacturing cable assemblies in the United States and Canada, and internationally ISO 9001:2015 certified as well, while holding to the practices outlined in IPC/WHMA-A-620 Standard Revision E. We also utilize automated work instruction systems developed by our partners at Scout Systems, which both help us to avoid errors as much as possible, and identify needs for improvement with the utilization of any new or unique wire or cable assemblies process, unusual parts, or special products.

Ready to move forward? Call us or contact us at [email protected] so we can review your drawing, specifications, and quantity needs and give you a quote as soon as possible!