Technical Cable Applications provides cable harness manufacturing for automotive and automotive-adjacent corporations and businesses in need of high-quality wire harnesses. TCA is one of the top automotive wiring harness manufacturers in the nation. We also provide cable manufacturing for construction, telecommunications, energy, marine, transportation, locomotive, and medical applications.

This means you can choose our company for all your cable assembly and wiring harness needs, whether you need improved harnesses for a new fleet of vans or are building an entirely new factory for assembling vehicles or other vehicle-related products. We provide both custom and OEM automotive wire harness and cable assembly services, and source components from America or our nearshore partners in Guadalajara whenever possible to provide faster lead times and higher quality control.

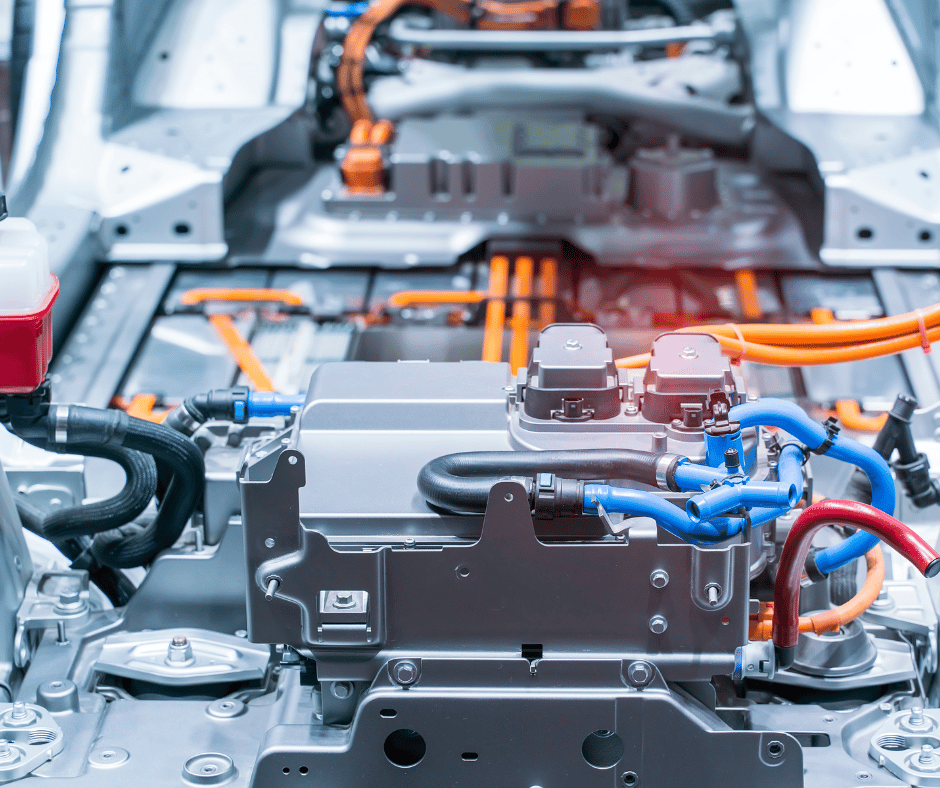

Automotive Wire Harness Manufacturing

For those unfamiliar with the vehicle assembly wire industry, the most common assembly cable types used are molded wire assemblies, specifically battery cable assembly products, since even traditional gas or diesel-powered vehicles still use batteries for electronic needs. As for wiring, primary wire types like GXL or SXL are also another highly common type we can manufacture. These are designed to fit within small spaces while being heat-resistant and maintaining insulation in external portions of vehicles.

Shielded cable styles are also often used within vehicles where extra wear and tear is expected, and flat ribbon assemblies may also be used for high-resolution electronic displays that are being used more nowadays by many electric vehicle brands.

Wiring Harness Manufacturer for EVs, Charging Equipment, Batteries, and More Automotive Wire Applications

We are able to provide custom wire harness and assembly services for all of these and so much more, and we are UL certified for the manufacturing of transportation wire harnesses in the United States and Canada, and internationally, ISO 9001:2015 certified as well. We also hold to the quality control standards of IPC/WHMA-A-620 Standard Revision E and use automated work instruction systems from our partners at Scout Systems, to ensure that every order goes out perfectly while keeping our processes safe, efficient, and thorough.

Founded in 2002, our facility in the Pacific Northwest is now one of the most advanced in the entire nation. Our shipping partners help us to ship throughout North America and internationally as well, and we are proud to have served so many great companies across the US, Canada, and the world. Please send your cable drawing, specifications, and any NDAs or additional info needed to [email protected] to get started!