Are you in need of a team of North American cable assembly experts to handle your ongoing cable orders? Choose Technical Cable Applications, based in the Seattle area of the United States! We will be your best asset as you look to improve your product, factory, or facility’s quality and reliability. Our highly reputable and tightly quality-controlled wire harness manufacturing processes result in reduced headaches for you!

Certified for OEM Harness Assemblies and Custom Cable Assemblies

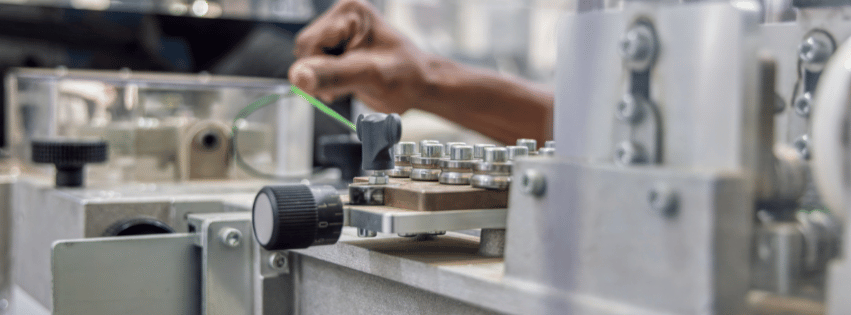

We are ISO 9001:2015 certified, UL certified, and hold to IPC/WHMA-A-620 Standard Revision E for our inspection and quality control standards to ensure that your wire harness orders and custom cable assemblies are one hundred percent reliable and manufactured exactly to your specifications. We also utilize custom automation work instruction software from our partners at Scout Systems to improve and maintain our crimping, tinning, and assembly work and automate whatever we can to reduce the risk of errors.

Cable Assembly and Wire Harness Manufacturing in North America

You will also find that Technical Cable Applications is the perfect fit for your needs if you are looking to reduce your business’s reliance on overseas parts, equipment, and products. Not only do we have our highly advanced assembly manufacturing facility in the Puget Sound, but we also partner with two excellent facilities in Guadalajara that enable our clients to indirectly take advantage of nearshore manufacturing processes and solutions. We have reduced our reliance on overseas parts as much as possible, which equates to faster lead times for your off-the-shelf wire harness needs, and lower MOQs for your prototype wire harness needs and custom cable assemblies.

OEM Patch, USB, and Power Cables

Not only do we offer custom cable assemblies, but we also have garnered a reputation for being a high-quality and reliable source for OEM patch and power cable needs as well. Do you need new orders of an existing cable or cable assembly that the original assemblies manufacturer no longer makes? Or perhaps you want to move the manufacturing of an OEM cable to North America for regulatory or lead time reasons. Either way, Technical Cable will be a perfect partner for you as well.

Custom Cable and Wire Harness Experts

Technical Cable Applications of the Pacific Northwest is now one of the top harness assembly manufacturers in the United States. Our engineers and cable assembly experts are some of the most experienced in the industry, and we use highly advanced technology and equipment to manufacture cables at scale, but with high customization and flexibility to enable your boutique and unusual requests. We have been growing continually and steadily in our technological capabilities, along with continual upgrades to our facilities and partnerships since our founding in 2002. This has helped us to grow our customer base thoroughly while retaining our top partners, thanks to our ability to continue offering custom and low MOQ wire harnesses as we grew our capabilities for larger orders.

Please contact us at [email protected] with your cable drawing and any NDAs or additional information required*, so we can get you a quote as soon as possible.

*Technical Cable Applications (TCA) is a contract manufacturer and produces products according to the customer’s requirements, Engineering Design Drawings and Bill of Materials (BOM) as provided.

TCA procures items as specified in customer provided documents and does not deviate without consent from the customer.

TCA does not verify if components specified on customer documents are RoHS/REACH/etc. compliant, as that is the responsibility of the design authority to ensure that they’re spec’ing in RoHS/REACH/etc components at the design level if that is what they require.

TCA ensures the product is built to customer requirements as stated in our CoC which is included on each packing slip.