The First Article Process

The First Article Process is a crucial part of production requirements at Technical Cable Applications. The process confirms that an assembly has been designed as intended and that documentation is complete and interpreted correctly. It verifies that proper assembly techniques and tooling are used and assures that later builds of product are produced without variation.

Quotation

At TCA the first article process starts before an order is ever placed. During the quote process the customer drawings or specifications are carefully reviewed. This assures that all the elements for successful production are included.

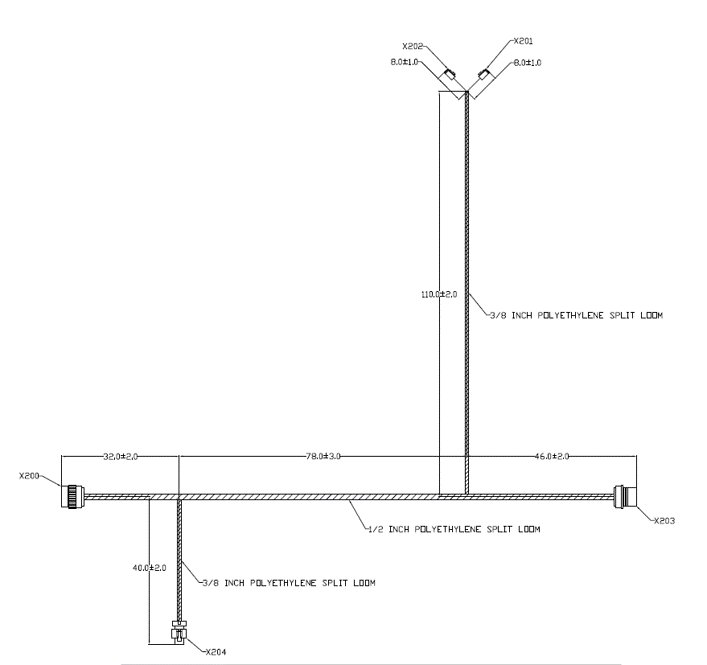

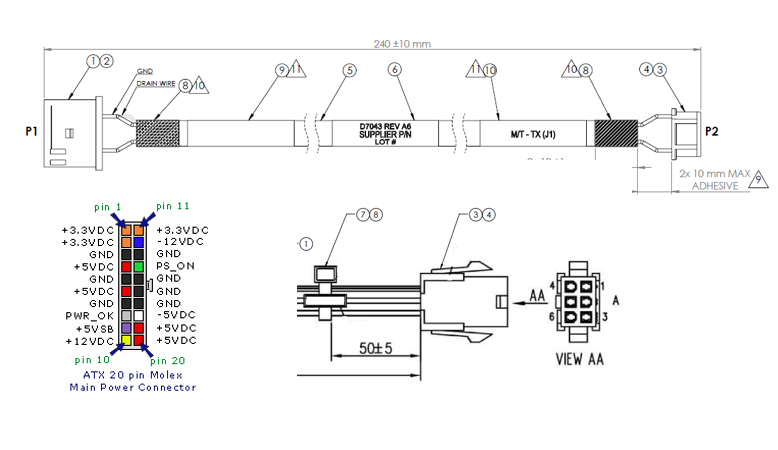

The bill of materials is evaluated to make certain all the components shown on the drawing are called out and in the correct quantities. They are looking for any obvious material conflicts such as wire size /terminal compatibility. A mismatch like this could be because the insulation diameter or wire AWG is too large or too small for a terminal. Discrepancies like this could affect the integrity of the product or damage tooling.

The drawing is checked for clear dimensional criteria and for tolerances that are achievable for cable assemblies. It is also reviewed for references to any documents or quality standards other than IPC. If other quality documents are referenced Technical Cable Applications quotations specialists assure those documents are on file.

Tooling and Test Fixtures

During the quote process tooling requirements are checked for all the components. At Technical Cable Applications the component manufacturers recommendations are checked to assure that the right tools are on hand. It is verified that mating test fixtures are available for all connectors. If either of the tooling or test fixtures are not on hand, they will need to be ordered for the build.

Work instructions

Work instructions are created by Technical Cable Applications production engineers. These seasoned professionals have broad knowledge and training in cable assembly production and quality standards. For cable assemblies this would be to the IPC/WHMA -620B standard. If there are other production or quality standards called out in the customer documentation the production engineers will obtain a copy and make sure they are part of the process.

The work instruction lists all the machines, tools, fixtures, and materials used. It contains set up and programming instructions for any equipment used.

A Detailed Accounting

As the production engineers build the first article, they keep a detailed step by step accounting for every process used to build the assembly and in the order it is to be completed. Special instructions and cautionary notes are often part of the instructions with detailed pictures for each step included. The completed work instructions are controlled on a central server and every workstation has a computer terminal with to access the information.

In the event the production engineer finds any issue, conflict or has any concerns during the first article build the Sales Specialist is notified, the customer is contacted, and the concern and any resolution are documented.

Test and Inspection

Test and inspection steps are included in the work instruction including inspections where a process might be hidden by a subsequent step.

The finished first articles are sent to the Technical Cable Applications quality department where the assembly undergoes a series of dimensional and quality checks to assure that the assembly meets or exceeds the customer specifications. The first article assemblies are tested and sent to packaging to be shipped with first article documentation to the customer.

Validation

Once the first article is inspected, tested, and approved by the customer the work instructions are validated by Technical Cable Applications quality personnel. Production can then be scheduled for the assemblies.

Contact

Technical Cable Applications is an ISO9001:20015 registered company. Please contact the Technical Cable Applications sales team for help with all of you cable assembly needs.