Bills of Material and Material Callouts

Material callouts

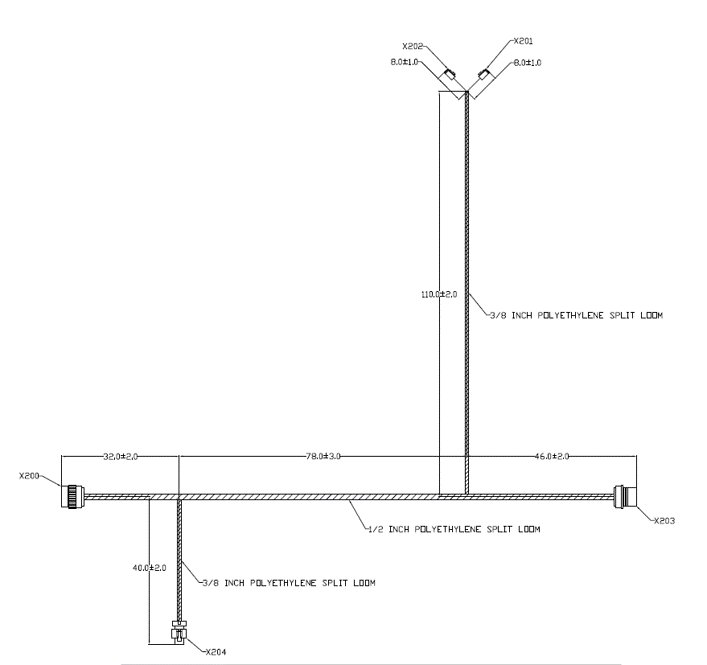

It can be incredibly helpful on a drawing to call out with a pointer where material should be used on the drawing.

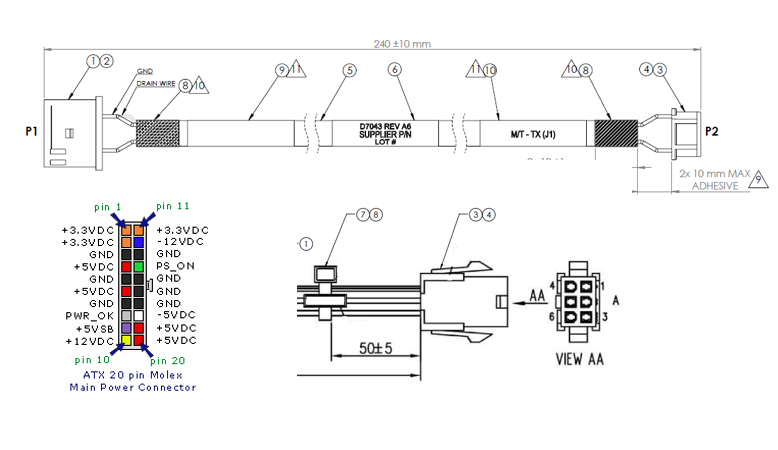

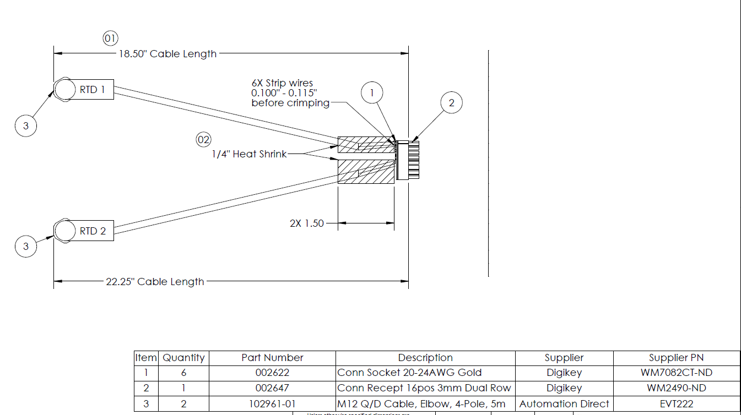

- Best practice is to callout items numbers on the physical layout, usually with a circled BOM item#.

This makes it much easier to identify which parts should be used together and where they should be used.

This makes it much easier to identify which parts should be used together and where they should be used.- It’s also sometimes helpful to simply write part numbers directly next to items on a drawing.

Bills of Material

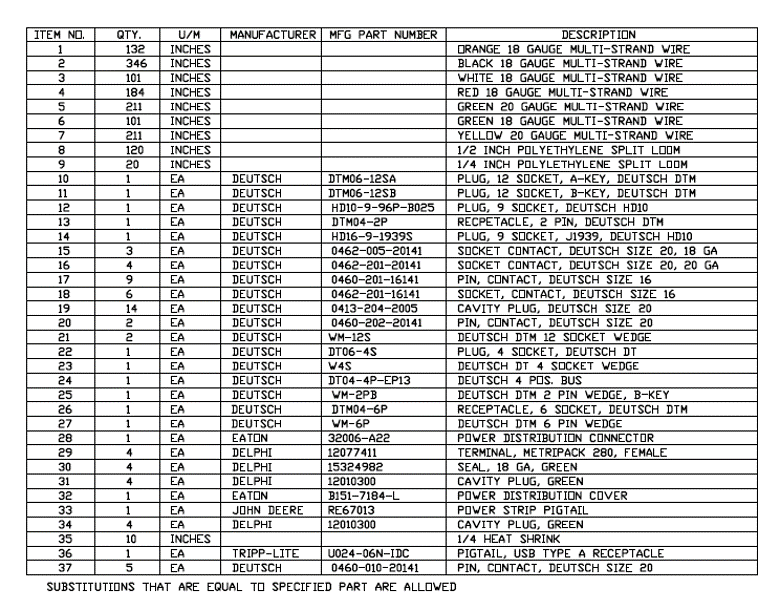

- Best practice is to give a table with item numbers, those item numbers can be used for material callouts in the drawing.

- Manufacturer part numbers for all components is ideal for all parts, except maybe where we stock generics like UL wire and heatshrink

- We can certainly help with simplifying a BOM, but knowing exactly what materials we’re expected to use can be very helpful!