Types of USB Cables

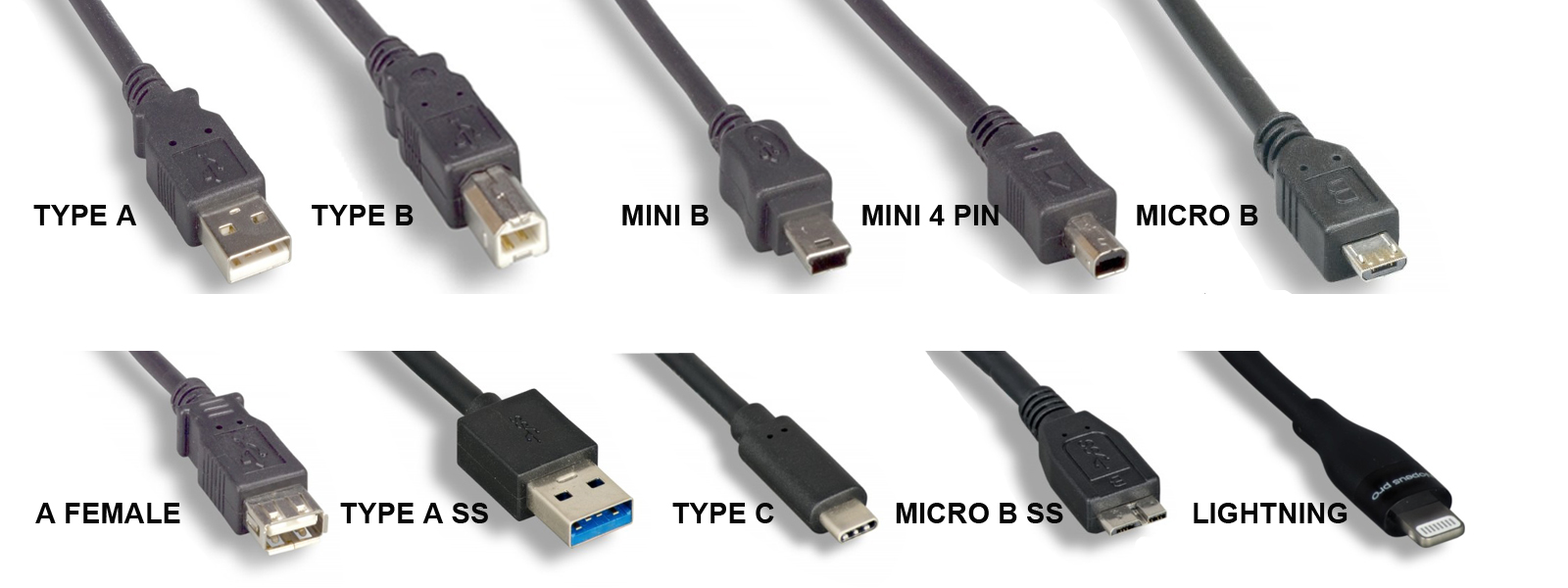

USB Assembly Types Including Mini USB, Micro USB and USB Standard

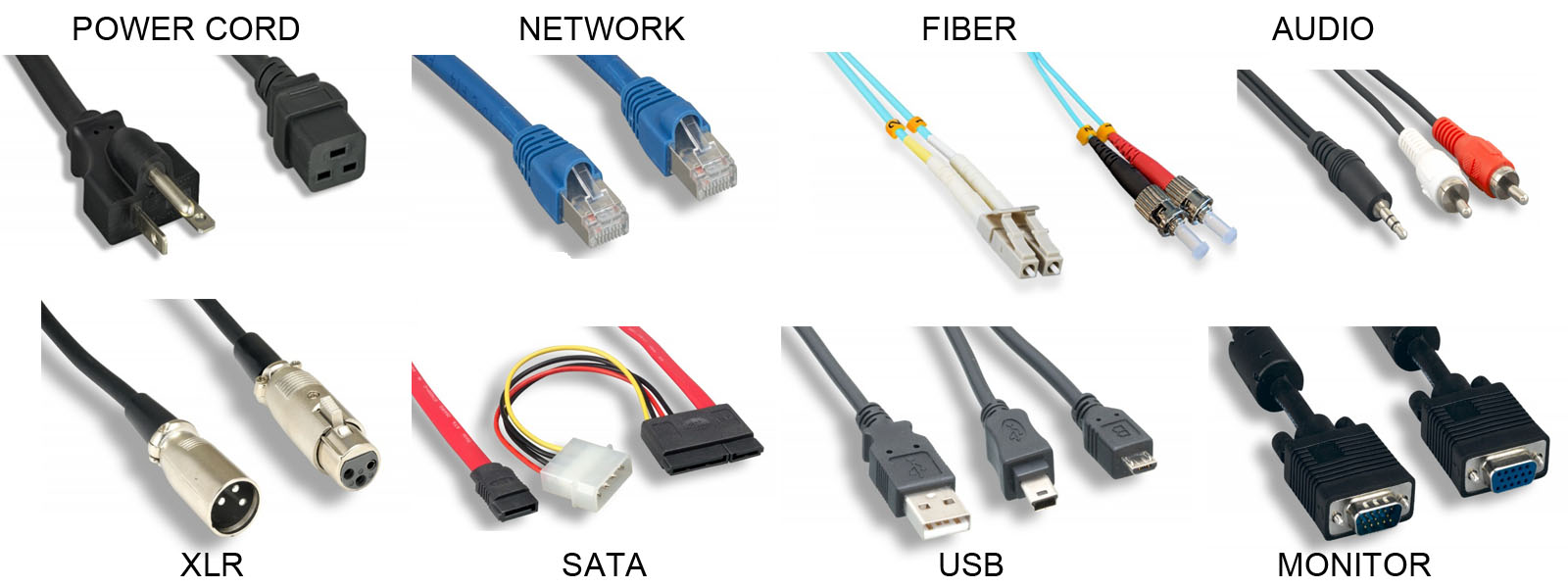

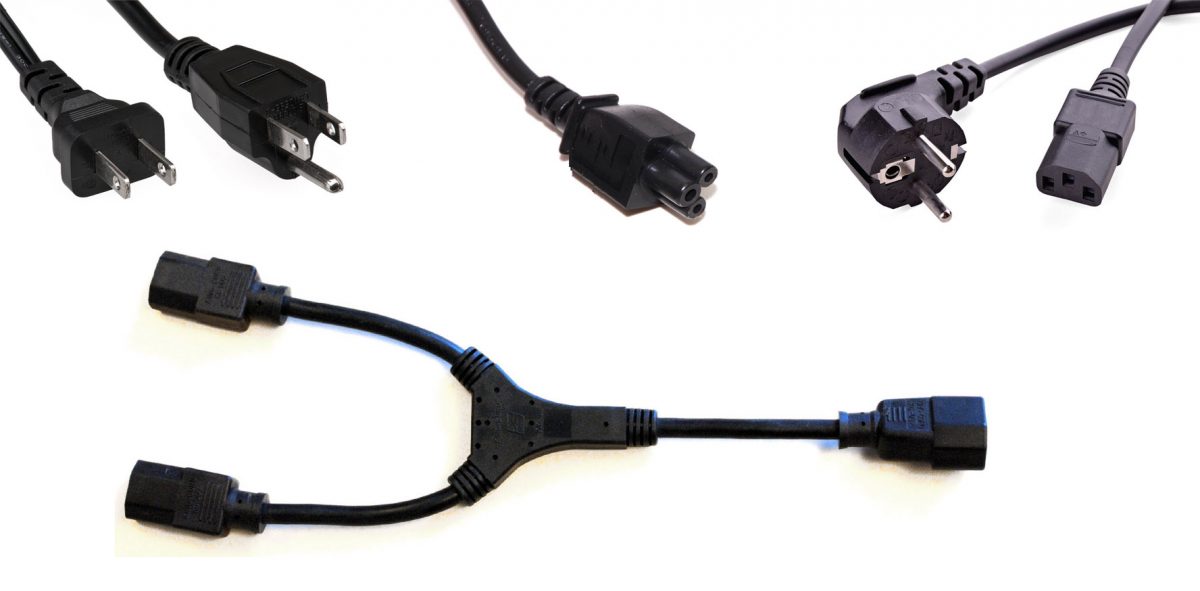

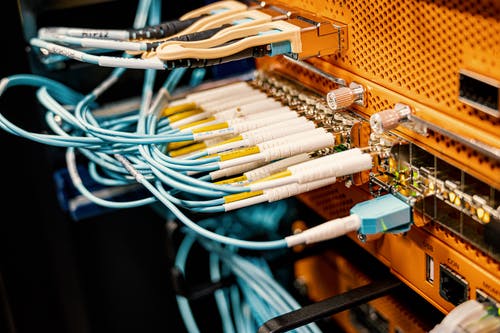

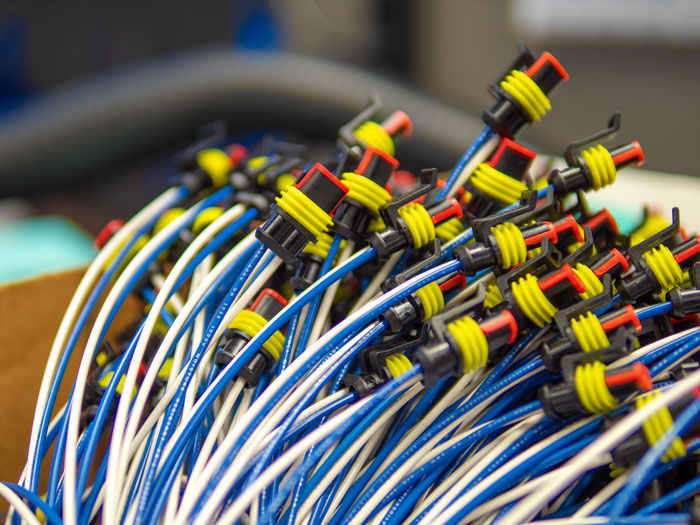

Technical Cable Applications is your one-stop shop for Off-The-Shelf USB cable assemblies. TCA offers a variety of USB 2.0 through USB 4 2.0 standard cables with various connector types in different lengths. This post is intended to be a comprehensive summary of the types of USB cables that are commercially available, what types we most commonly manufacture, and what the most cutting edge technology in the USB connector world is now.

USB Standards

The Universal Serial Bus standard released in 1996. The first standard, USB 1.0, was much faster than the typical serial or parallel connections available at the time. The USB standard evolved quickly. The following is a summary of major speed increases in the USB Standard, and how commonly these standards are used today.

| Standard | Speed | Current Usage | Year Introduced |

| USB 1.0 | 12 Mbit/s: Full Speed (FS) | Rarely used today | 1996 |

| USB 2.0 | 480 Mbit/s: High Speed (HS) | Still used frequently as the minimum speed of cheaper USB-A cables | 2000 |

| USB 3.0 | 5 Gbit/s: SuperSpeed (SS) | Most popular USB edition for consumer grade electronics to this day | 2008 |

| USB 3.1 | 10 Gbit/s: SuperSpeed+ (SS+) | Mostly surpassed by 3.2 | 2013 |

| USB 3.2 | 20 Gbit/s: SuperSpeed+ two-lane | Top tier USB cables prior to 2019 and still used far more frequently than 4 or 4 2.0 | 2017 |

| USB 4 | 40 Gbit/s: two-lane | Becoming more common but still less used than 3.0 to 3.2 | 2019 |

| USB 4 2.0 | 120 ⇄ 40 Gbit/s: asymmetric | Niche applications for pushing two data streams at once, not commonly used yet | 2022 |

USB-A and USB-C Port Assembly

Connector Types

USB or Universal Serial Bus cables come with a variety of different connector types and the cable varies by the device requirements. The connector types include Type-A, Type-B, USB-C, Mini-A, Mini-B, Mini-AB, Micro-A, and Micro AB. There are also Super Speed versions of these connectors available. Here’s some info about the timeline of introductions, and how commonly these are seen today.

| Connector | Variations | Current Applications | Year Introduced |

| Standard-A | 1.0, 1.1, 2.0, SuperSpeed | The most common and cheapest USB connector | 1996 |

| Standard-B | SuperSpeed | Niche but used for hardware like printers or musical equipment | 1996 |

| Mini-A | n/a | Previously used for mobile phones but eclipsed by Micro B, then Type-C | 2000 |

| Mini-AB | n/a | Rarely used at any point, briefly used for HTC phones | 2000 |

| Mini-B | n/a | Previously used for digital cameras but eclipsed by Micro | 2000 |

| Micro-A | SuperSpeed | Used for host devices in some cases like desktop computers | 2007 |

| Micro-B | SuperSpeed | Used for Android phones. and mobile devices extensively prior to the introduction of Type-C | 2007 |

| Lightning | n/a | Apple mobile charger, now replaced by Type-C for new devices | 2012 |

| Type-C | n/a | The new standard for premium speed, charging, and both desktop and mobile applications | 2014 |

Countless Configurations

Technical Cable Applications’ offerings include cables configured with all the connectors listed above and far more beyond. The company also has a large inventory of adapters for USB to Ethernet, USB to HDMI, USB to Serial, and more, plus full flexibility with crimping, tinning, and configuration for any complex assemblies.

Custom Requirements

In addition to our OEM offerings, Technical Cable Applications’ skilled specialists are ready to help with any custom cable assembly requirements you might have. TCA stocks cables, connectors, and materials by the thousands and can custom build dies and molds not on hand.

Please contact the TCA Technical Sales Team for assistance with all your cable assembly needs by reaching out to [email protected] or giving us a call!

*Please provide cable drawings and all documentation available when contacting us so we can quickly give you an accurate quote. We will do our best to research specifications and materials if a drawing is not available, but if no documentation exists that may need to be created first before we can proceed.