There are a number of reasons you may have your assemblies built onshore. You may also be thinking about bringing product back onshore in today’s market, but there can still be good reason to consider offshoring your assemblies. Here we will explore onshore versus offshore manufacturing of cable assembles. Technical Cable Applications can support both your onshore and offshore production requirements.

Offshore

The primary reason to consider offshore manufacturing is to cut the price of materials. Labor rates and component costs are typically much lower in countries like China and Taiwan. Established manufacturers offer quality that rivals those of domestic goods. Reputable manufacturers of electronics have the same certifications needed to meet requirements like UL and CSA and will also meet RoHs and conflict minerals requirements.

However, transportation and tariff costs must be taken into consideration when dealing directly offshore. Travel to visit and set up relationships and adding additional employees to assure quality also come at a price. Lead times are generally much longer, and quality issues can be difficult to resolve. Cultural and language differences can result in miscommunication that impact the planning, or quality, or cause production delays. It is essential that the cable concept is stable, and purchases must be made in advance of demand. Higher quantity minimum orders are usually required by offshore suppliers.

Managing the process can be overwhelming.

Onshore

Lower cost travel to visit vendors allows for meetings and vendor audits that might otherwise be impossible. This makes establishing vendor relationships much easier.

Onshore development of new product can be fast tracked with initial deliveries in weeks instead of months. There is greater control over product quality. Product changes can often be implemented without delay. Domestic manufacturers allow for purchasing in much smaller quantities. In addition, more flexible delivery schedules can be realized and this reduces inventory costs. The shorter distances also greatly reduce delivery time.

And there is no doubt that “Made in the USA” can help sell product.

The Solution

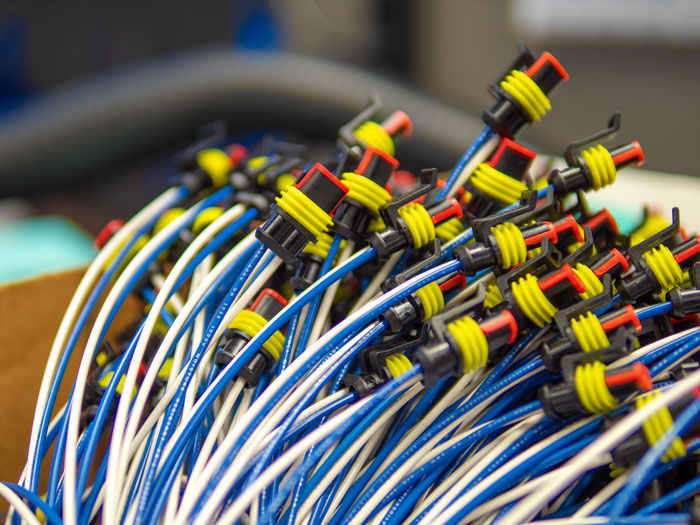

Technical Cable Applications, located in Auburn Washington, is a large domestic contract manufacturer of Cable Assemblies. Utilizing the latest high speed manufacturing equipment with over 60 skilled employees provides product “Made in the USA” at extremely competitive prices.

Offshore Manufacturing

TCA also has unique offshore partnerships with reputable manufacturers. This has allowed the company to create new rules for importing custom assemblies. Usually, manufacturers are burdened with long lead times and high minimum order quantities when importing custom assemblies. Technical Cable Applications can bring in offshore product in smaller quantities with much shorter lead times than tradition allows.

Our domestic quality engineers are here to help assure that your cable meets criteria and the final product meets specification. The technical team manages the transaction eliminating all the difficulties of buying offshore. Tariff and standard transportation costs are typically included in the pricing to eliminate hidden costs.

Technical Cable Applications is ready to help you decide which outsource option is best for you and manage your production builds onshore or offshore. Contact our Technical Sales team for more information.